LineVac Exair

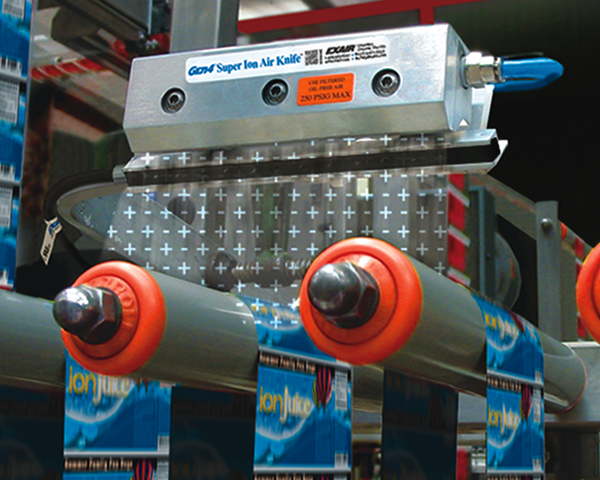

Move parts, materials or scrap - without using moving parts!

- Easily move granular material such as pellets or grains!

- Easy to install, can fit into existing pipelines!

- Various materials and diameters available for all applications!

- No moving parts, so no maintenance required!

Description

What are LineVac Exair pneumatic conveyors?

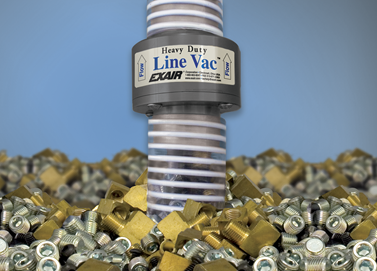

EXAIR LineVac pneumatic conveyors, or LineVac, are devices that, when connected to any standard pipe or hose, transform into powerful vacuum transport systems. Their compact design and variety of diameters allow for high material discharge volumes, providing good transport capacity over long distances. The suction of the unit can be adjusted by reducing the input pressure with a regulator.

These units only require compressed air to operate. They have no moving parts that need maintenance or require electrical power. EXAIR air-driven conveyors are ideal for applications in pneumatic conveying solutions for bulk materials. Additionally, they provide energy-efficient LineVac conveyors that contribute to cost-effective operations in industrial environments.

Applications

Loading hoppers of injection molding machines.

Transport of small parts between assembly lines.

Raw material transport.

Filling operations.

Removal of burrs or debris in processes.

Cleaning of work areas.

Fabric or plastic scrap collection.

Applications

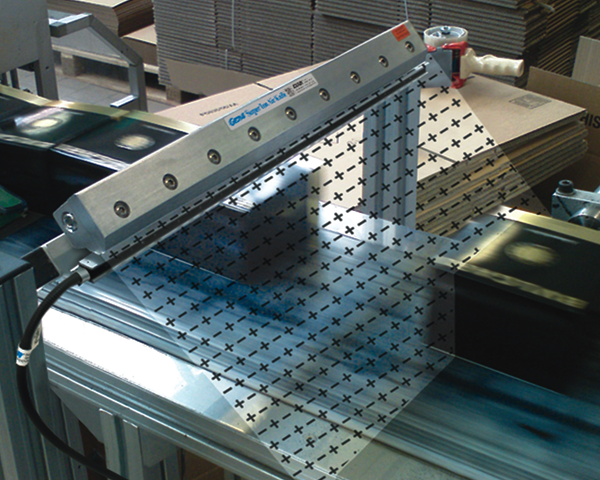

EXAIR pneumatic conveyors are compact.

Silent.

No moving parts.

Works with standard hose.

No moving parts. Maintenance free.

Available in various diameters and powers.

High conveying capacity. Pneumatic conveying solutions for bulk materials.

Videos

- How to Install an Exair LineVac.

- Increase conveying capacity with a drill bit.

- Heavy-Duty LineVac.

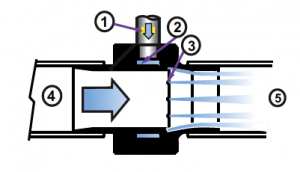

how does the exair Live Vac work?

The Compressed Air flow is injected into the system through the inlet (1️⃣) into an annular chamber (2️⃣). Under these conditions, air enters the device through the engineered directed orifices (3️⃣) . The generated air gusts create a suction of atmospheric air (4️⃣) which produces an air acceleration that pulls the material into the area (5️⃣) to be transported either vertically or horizontally. This effect is also known as the venturi effect. The conveying capacity will be limited to the density of the product to be conveyed, as well as the vertical and horizontal distance that needs to be covered.

The Compressed Air flow is injected into the system through the inlet (1️⃣) into an annular chamber (2️⃣). Under these conditions, air enters the device through the engineered directed orifices (3️⃣) . The generated air gusts create a suction of atmospheric air (4️⃣) which produces an air acceleration that pulls the material into the area (5️⃣) to be transported either vertically or horizontally. This effect is also known as the venturi effect. The conveying capacity will be limited to the density of the product to be conveyed, as well as the vertical and horizontal distance that needs to be covered.

Applications

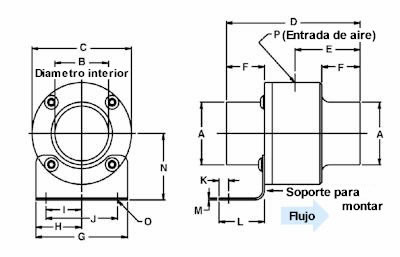

Dimensions

| Acero Inox. | Aluminum | Unidad | A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | D |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 6058 | 6078 | in | .38 | .19 | 1 | 2.18 | 1 | .63 | 1.25 | .62 | .41 | .82 | .17 | 1.13 | .06 | 1.07 | .18 | 1/8 NPT |

| mm | 10 | 5 | 25 | 55 | 25 | 16 | 32 | 16 | 10 | 21 | 4 | 29 | 2 | 27 | 5 | |||

| 6059 | 6079 | in | 0.5 | .31 | 1.25 | 2.62 | 1.23 | .75 | 1.25 | .63 | .34 | .68 | .13 | 1 | .06 | 1.18 | .16 | 1/8 NPT |

| mm | 13 | 8 | 32 | 66 | 31 | 19 | 32 | 16 | 9 | 17 | 3 | 25 | 2 | 30 | 4 | |||

| 6060 | 6080 | in | .75 | .50 | 1.88 | 3.88 | 1.88 | 1 | 2 | 1 | .76 | 1.52 | .25 | 1.38 | .06 | 1.44 | .20 | 1/4 NPT |

| mm | 19 | 13 | 48 | 99 | 48 | 25 | 51 | 25 | 19 | 39 | 6 | 35 | 2 | 37 | 5 | |||

| 6061 | 6081 | in | 1 | .75 | 2.13 | 3.88 | 1.88 | 1 | 2 | 1 | .65 | 1.3 | .26 | 1.32 | .06 | 1.56 | .20 | 1/4 NPT |

| mm | 25 | 19 | 54 | 99 | 48 | 25 | 51 | 25 | 17 | 33 | 7 | 34 | 2 | 40 | 5 | |||

| 6062 | 6082 | in | 1.25 | 1 | 2.38 | 3.88 | 1.88 | 1 | 2.5 | 1.25 | 1 | 2 | .31 | 1.61 | .06 | 1.68 | .28 | 1/4 NPT |

| mm | 32 | 25 | 61 | 99 | 48 | 25 | 64 | 32 | 25 | 51 | 8 | 41 | 2 | 43 | 7 | |||

| 6063 | 6083 | in | 1.5 | 1.25 | 2.75 | 4.38 | 2.13 | 1.25 | 2.5 | 1.25 | .86 | 1.73 | .25 | 1.44 | .06 | 1.88 | .28 | 3/8 NPT |

| mm | 38 | 32 | 70 | 111 | 54 | 32 | 64 | 32 | 22 | 44 | 6 | 37 | 2 | 48 | 7 | |||

| 6064 | 6084 | in | 2 | 1.75 | 3.25 | 4.38 | 2.13 | 1.25 | 3 | 1.5 | 1.17 | 2.34 | .28 | 1.48 | .06 | 2.13 | .28 | 3/8 NPT |

| mm | 51 | 45 | 83 | 111 | 54 | 32 | 76 | 38 | 30 | 59 | 7 | 38 | 2 | 54 | 7 | |||

| 6065 | 6085 | in | 2.5 | 2.25 | 3.75 | 4.38 | 2.13 | 1.25 | 3 | 1.5 | 1 | 2 | .31 | 1.44 | .06 | 2.38 | .28 | 3/8 NPT |

| mm | 64 | 57 | 95 | 111 | 54 | 32 | 76 | 38 | 25 | 51 | 8 | 37 | 2 | 60 | 7 | |||

| 6066 | 6086 | in | 3 | 2.75 | 4.25 | 5.63 | 2.75 | 1.75 | 3.25 | 1.63 | 1.20 | 2.41 | .41 | 1.44 | .06 | 2.63 | .28 | 1/2 NPT |

| mm | 76 | 70 | 108 | 143 | 70 | 45 | 83 | 41 | 31 | 61 | 10 | 37 | 2 | 67 | 7 | |||

| 6067 | 6087 | in | 4 | 3.75 | 5.25 | 5.63 | 2.75 | 1.75 | 3.25 | 1.63 | 1.34 | 2.7 | .31 | 1.59 | .06 | 3.13 | .28 | 1/2 NPT |

| mm | 102 | 95 | 133 | 143 | 70 | 45 | 83 | 41 | 34 | 69 | 8 | 40 | 2 | 80 | 7 | |||

| N/A | 6088 | in | 5 | 4.75 | 6.25 | 5.63 | 2.75 | 1.75 | 4.13 | 2.06 | 1.70 | 3.47 | .33 | 1.52 | .06 | 3.63 | .28 | 1/2 NPT |

| mm | 127 | 121 | 159 | 143 | 70 | 45 | 105 | 52 | 43 | 88 | 8 | 39 | 2 | 92 | 7 |