COMPRESSED AIR CONDENSATION MANAGEMENT

Protecting Your Compressed Air from Condensation.

When moisture is not removed correctly from your compressed air system, it could travel through your airlines and leave you with unexpected damage and decrease production efficiency. The presence of water will lead to the creation of rust in the air piping system.

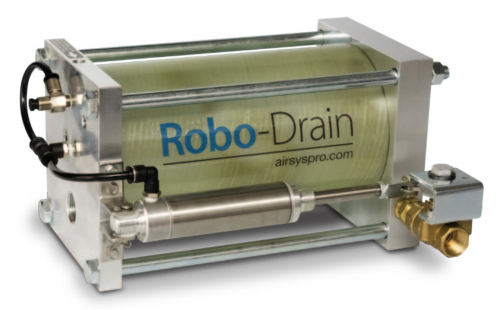

However it is quite simple to prevent these issues. All that needs to be done is to regularly ensure that all drains are working and removing condensate from the system efficiently. If possible, make sure all your drains are zero-loss, as you want to get rid of moisture not compressed air that equals wasted energy.

DO NOT leave manual valves slightly open to consistently drain the condensation. Leaving the valve open will eliminate the need for continued attention, and it will be effective at getting the condensation out the system. This is tempting on drain points that have a high volume of condensation. However, this creates an apparent compressed air leak, and even a small continual leak will waste several hundred dollars in annual energy cost.

Benefits of an Air Dryer

The most efficient way to prevent moisture from gathering is by installing an air dryer in your system. Dryers remove moisture so it does not condense and cause those problems. There are two types of dryer (refrigerated and desiccant) and the type you need depends very much on the type of air desired for your operation. You can browse our complete line of air dryers here.

The bottom line is you need to somehow manage the moisture that will develop in your air compressor system and a dryer is the optimal way to make this happen. It will keep your system up and running at its peak and avoid major expenses down the line.

Never under estimate the damage that can be caused by condensation. For questions, please contact our support team at support@airtec.global.

The Basics of the Line Vac

Learn MoreElectronic Flow Controller

EFC is a user-friendly electronic flow control for compressed air that is designed to minimize compressed air use on blow off, drying, cooling, conveying and static elimination operations.

Learn More