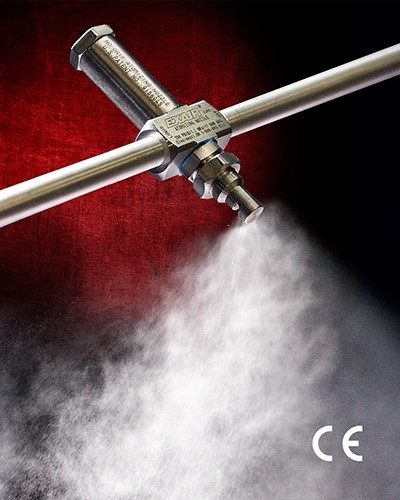

EXAIR’S NO DRIP SPRAY NOZZLE

Exair Helps You Conserve Valuable Resources and Increase Performance All at Once!

Spray nozzles are used for a wide variety of different tasks in different manufacturing contexts. In one, nozzles might be used to spray products down with water, and in another, they’ll be used to cover products with expensive chemical coatings or paint. Regardless of how they are used, leaky spray nozzles can be a major waste of resources. Even when the nozzles are only spraying water, enough wasted water eventually adds up.

In addition to waste of resources, leaky spray nozzles can create many other problems. Drips can ruin the appearance of painted or coated finishes or negatively affect product function on sealing or mating surfaces.

Building a Better Manufacturing System

Whenever Exair releases a new product, we can’t help but be pretty excited! Time after time, Exair demonstrates their dedication to quality and innovation, and the new No Drip Internal Mix Atomizing Nozzles are no exception. EXAIRs patented 1/4 NPT No Drip Internal Mix Atomizing Nozzle atomizes fluid and sprays at a right angle to the nozzle orientation. The right-angle orientation allows spray to be placed precisely where it is needed, even when the mounting and work areas are limited or cramped. The No Drip Nozzle otherwise functions as a spray nozzle should, but this nozzle has the added benefit of positively stopping liquid flow when compressed air is shut off.

EXAIR’s No Drip Internal Mix Atomizing Nozzles are available in five patterns: narrow-angle round pattern, wide-angle round pattern, flat fan pattern, deflected flat fan pattern and 360° hollow circular pattern. They are perfect for pressure fed applications that don’t require independent air and liquid control. Internal Mix, External Mix, No Drip External Mix, Siphon Fed and No Drip Siphon Fed are also available in 1/4 NPT or 1/2 NPT.

As with other Exair products, the No Drip Spray Nozzles are versatile components. Some of the applications the nozzles can be used in include painting, coating, rinsing, cooling, quenching, wetting (moistening), and humidification and dust control. The compact Atomizing Nozzles are fully adjustable, so you can easily minimize air and liquid consumption. Liquid and air caps are completely interchangeable, and all No Drip liquid nozzles are CE compliant and conflict mineral free.

Why We Do What We Do

At Airtec Global, our goal is to create efficient solutions for systems of all sizes and applications, and we enjoy highlighting the best in new technologies and products to help us achieve that goal. Because we only focus on only high quality products, you can be sure that any solution we suggest for your system is going to be one that saves you money in the long run, whether through decreased maintenance costs or decreased energy and resource expenditures. Contact us today to find out we can help you increase the functionality, durability, and efficiency of your system.

The Basics of the Line Vac

Learn MoreElectronic Flow Controller

EFC is a user-friendly electronic flow control for compressed air that is designed to minimize compressed air use on blow off, drying, cooling, conveying and static elimination operations.

Learn More