Cooling systems for dry machining - Cold Gun Exair

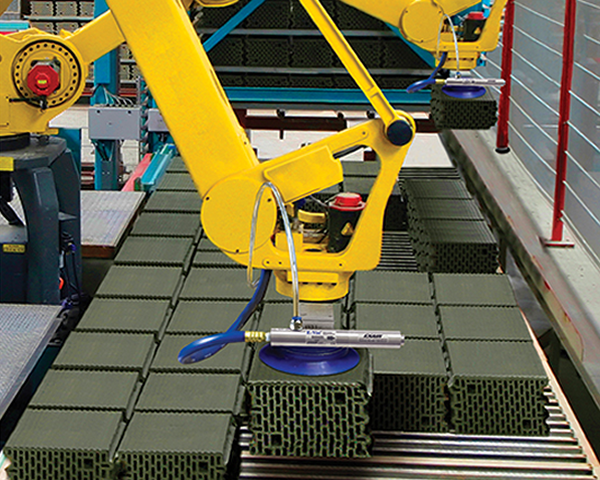

Move parts, materials or scrap - without using moving parts!

- Easily move granular material such as pellets or grains.

- Simple to install, can be retrofitted to existing pipelines.

- Various materials and diameters available for all applications.

Description

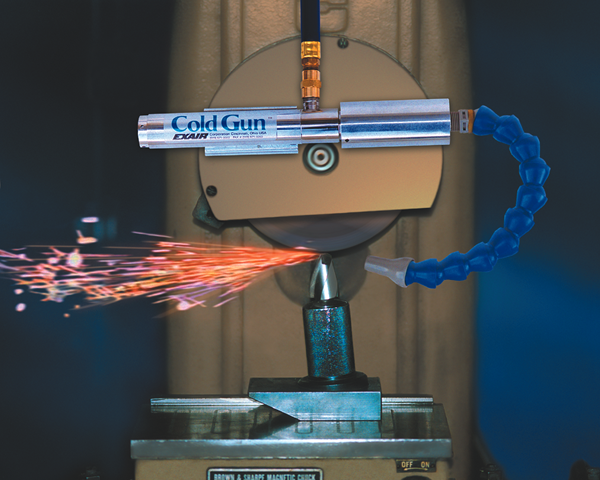

What is the Exair dry machining cooling system?

A new solution to an old problem. Heat build-up in dry machining operations reduces tool life and machining quality. Exair's Cold Gun dry machining cooling system produces a stream of clean, cool air, 28°C below the temperature of the compressed air supply. It is quiet in operation at only 70 dBA and has no moving parts and requires no spare parts. This air-cooled system removes heat from operations, prolonging tool life and increasing productivity in operations where liquid coolants cannot be used.

Exair's Cold Gun is also an alternative to costly fog cooling systems because it eliminates associated indirect costs such as the purchase and storage of cutting fluids, worker health problems due to breathing fog and the risk of wet, slippery floors.

Applications

Cleaning of coolant reservoirs.

Food processing.

Lathes and milling machines.

Floor cleaning.

Cleaning of machining centers

Drying of parts.

EDM machines.

Tank emptying.

Advantages

No moving parts. Maintenance free.

Stainless steel construction.

Works with any standard 30, 55 or 110 gallon drum.

Does not require electricity to operate.

Compact and easy to transport.

Spill protection valve included.

Pressure relief valve included.

How does the Exair Cold Gun work?

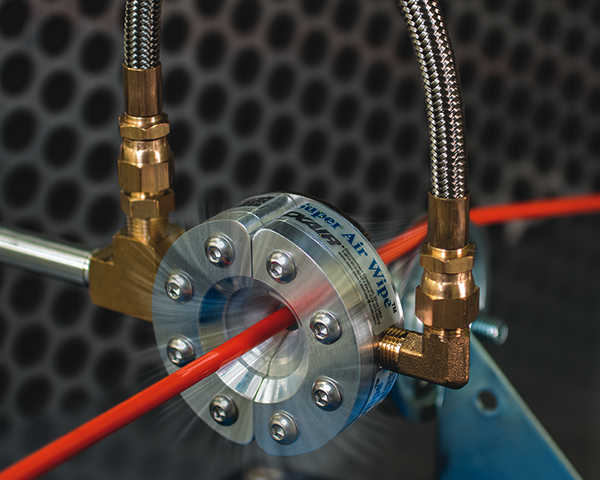

The standard cold gun and the Exair high power cold gun both have a built-in vortex tube to convert the compressed air supply they are fed with into two low pressure streams, one of hot air and one of cold air. The hot air stream from the cooling system is silenced and discharges through an exhaust at the rear of the device. The cold air discharges through a flexible hose, which is directed to the point of greatest heating, usually the point of contact of the tooling with the part. A magnetic base is used which is included in the system for easy mounting and high portability.

Equipment dimensions.