Sullair Two-Stage - 2-Stage Lubricated Screw Compressors from 150 hp to 600 hp

Sullair 2-Stage Lubricated Screw Compressors from 150 hp to 600 hp

Utilizing the latest technologies, equipment and manufacturing techniques, Sullair Two-Stage equipment designs, manufactures, assembles and tests the most innovative compressed air and vacuum products in the industry. Sullair products are known worldwide for their universally applicable design, exceptional craftsmanship and superior quality.

Description

- Multistage Air and Fluid Separation.

Double nested Optimizer™ separator elements reduce fluid leakage to a maximum of 1 ppm.

Reduced fluid leakage lowers fluid replenishment costs.

Folded Optimizer elements reduce initial pressure drop for greater efficiency and extend element life.

Easy to change with a built-in cover lifting device.

- Glass Fiber Fluid Filter

Aircraft-quality media provides better filtration

Up to 20% more efficient than conventional paper elements.

Extends compressor life.

- Optimalair® Heavy-Duty Intake Air Filter

Includes remote air intake connection.

Provides the industry's finest inlet filtration (99.95%+ / 0.4 micron overall efficiency).

Keeps fluid clean and prolongs the life of other internal components.

Reduces pressure drop over operating life, resulting in energy savings.

- Dual Stage Compressor

Supplies more air.

Reduces energy consumption.

Prolongs air end bearing life.

- Ease of Maintenance for Air Cooled Oil Cooler and Aftercoolers

Easy-to-remove panels provide access for cooler cleaning.

- Air End Coupled Motor through Non-Lubricated Flexible Coupling

Allows the use of a standard motor with NEMA frame.

Simplifies installation and start-up.

- Variable Capacity Control System with Spiral Valve Technology

Reduces operating costs at part load.

Reduces cycling load on the package.

Maintains constant plant pressure.

Simple control.

Reduces bearing load.

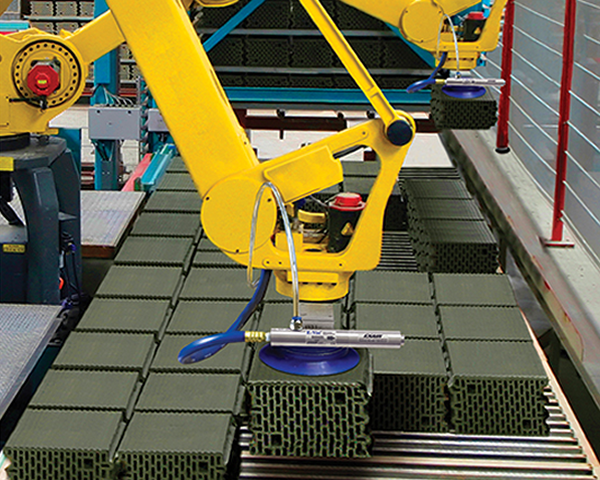

Applications

Sullair Supervisor™ Controller

Computer-compatible microprocessor controller featuring simple graphical illustrations of monitored functions and an easy-to-read keypad.

Constant pressure and temperature readout.

On-demand readout of all operating and maintenance conditions.

Monitors key functions and safety shutdowns.

Automatic restart in case of power failure.

Dual control provides automatic start and stop operation.

Leadership and sequencing with multiple compressors.

Preventive maintenance and service schedule.

Logs operating hours in “On”, “Loaded” and “Consumable parts”.

Fault history with sensor readings.

Help” key provides built-in troubleshooting.

Advantages

Easy Maintenance

Access to all critical components even with a sound enclosure installed. End-to-End Time-Tested Design

Reduces pressure drop across stages.

Easy serviceability. NEMA 4

Wye-Delta starter for smoother starting. Bearing Fluid Reservoirs

Ensure fluid is available at start-up.

Prolong air end life.