AVOID PRODUCTION DOWNTIME: THE BENEFITS OF MONITORING COMPRESSED AIR AND GAS QUALITY

In the fast-paced world of manufacturing, minimizing production downtime is critical. An effective strategy to achieve this is by utilizing monitoring equipment to maintain and ensure the quality of compressed air and gases. In this blog, we explore the benefits of using monitoring equipment, discuss the ISO 8573-1 Standard, and explain how these practices can help your business save time and money.

The Advantages of Monitoring Equipment

Monitoring equipment for compressed air is a vital tool in maintaining operational efficiency across various industries. By providing real-time data, this technology enables the timely detection of issues, allowing for informed decision-making and swift corrective actions for your equipment. Different industries, from food processing to pharmaceuticals, have unique requirements for compressed air quality, making the precision and reliability of monitoring equipment even more critical.

Early identification of potential problems is crucial in preventing costly production downtime. By monitoring your systems, you can quickly pinpoint issues within the generation, treatment, and filtration stages of compressed air systems. This proactive approach guarantees that minor issues are addressed before they escalate into major disruptions.

Understanding ISO 8573-1 Standard

One effective method for ensuring air quality is adhering to industry standards. The ISO 8573-1 Standard is a critical benchmark for industrial compressed air quality. This standard outlines the permissible levels of contaminants in compressed air and provides guidelines for achieving and maintaining these levels. By familiarizing yourself with these guidelines and implementing the recommended practices, you can significantly improve the quality and reliability of your compressed air systems.

Compliance with ISO 8573-1 not only helps in maintaining high standards of air quality, but also plays a vital role in preventing production downtime that is caused by contamination issues. Adhering to this standard confirms that your compressed air systems operate efficiently and safely, ultimately leading to improved overall productivity and reduced operational costs. By taking the proactive steps to comply with ISO 8573-1, your business can achieve a higher level of operational excellence and reliability.

Learn More in Our Webinar

To explore the benefits of monitoring equipment and its role in preventing production downtime, we invite you to watch our webinar. In this session, we showcase various industry applications, helping you find solutions tailored to your specific needs. The insights provided within our webinar are invaluable for enhancing your operational processes. Whether you operate in food processing, pharmaceuticals, or manufacturing, you’ll gain valuable insights to enhance your operations and reduce costs. Additionally, you will gain a deeper understanding of how adhering to the ISO 8573-1 Standard can enhance the quality and reliability of your compressed air systems.

This session covers:

- Understanding the ISO 8573-1 standard

- Identifying critical points for monitoring

- Optimizing air generation and demand

- Applications in different industries

- Installation tips

- Comparing fixed and portable units

- Conducting quality audits

At Airtec, we focus on educating our customers and providing best practices to meet these changing requirements. Our goal is to help businesses stay compliant and operate efficiently.

Please refer to our latest webinar below:

Airtec’s Role and Expertise

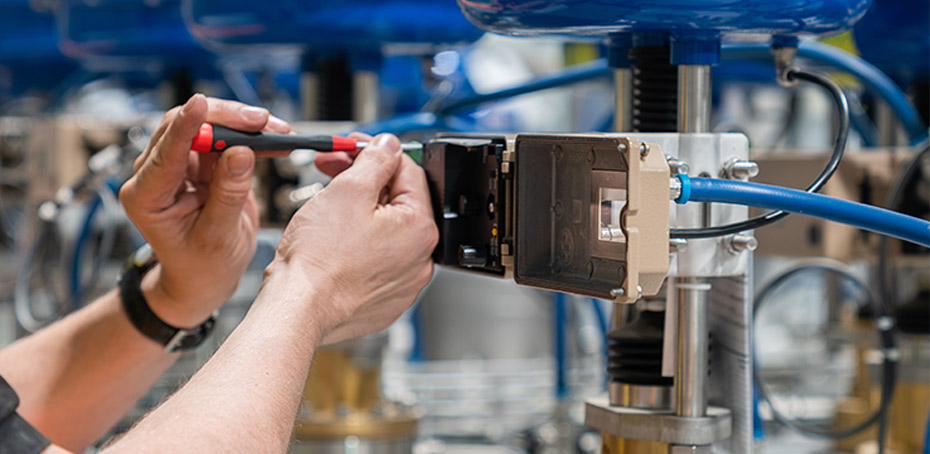

With years of experience using SCADAR equipment, Airtec’s technicians are specialists in installation and reporting. Our expertise ensures customer satisfaction and reliable solutions for your business.

If you’re interested in learning more about the benefits of monitoring your compressed air and gas quality or how you can ensure industrial compressed air quality with the ISO 8573-1 Standard, please feel free to reach out to us at Airtec anytime! We have experience with compressed air systems of all sizes and levels of complexity and are more than ready to help you build a better system!

The Basics of the Line Vac

Learn MoreElectronic Flow Controller

EFC is a user-friendly electronic flow control for compressed air that is designed to minimize compressed air use on blow off, drying, cooling, conveying and static elimination operations.

Learn More