Vortex Tubes & Spot Cooling Products

Take control of your temperature with Airtec’s cooling products. With Airtec’s carefully-selected spot cooling solutions, you can be sure that your production will be safe from the risks associated with increased temperatures, such as damage to electronics and overheating. You can also use enhanced temperature control to reduce moisture and contaminant buildup, further ensuring that you have an efficient production line. Keep the sensitive electronic elements of your system safe with Airtec’s cooling solutions.

At Airtec, we want to simplify compressed air. By helping everyone understand the basics of compressed air and by bringing specialized services to the global industry, we will help make compressed air use more efficient worldwide, one kilowatt-hour at a time. Call or email us for quote, and find out how you can start saving today.

Vortex Tubes & Spot Cooling Products We Use

Vortex Tubes

A low cost, reliable, maintenance free solution to a variety of industrial spot cooling problems. Using an ordinary supply of compressed air as a power source, vortex tubes create two streams of air, one hot and one cold, with no moving parts.

Cold Gun Aircoolant Systems

A new solution to an old problem. Heat build up on dry machining operations reduces tool life and machining rates. The Cold Gun Aircoolant System produces a stream of clean, cold air at 50°F (28°C) below supply air temperature. Operation is quiet and there are no moving parts to wear out. It will remove heat to prolong tool life and increase productivity on machining operations when liquid coolants cannot be used.

Adjustable Spot Cooler

A low cost, reliable, maintenance free solution to a variety of industrial spot cooling problems. With the turn of a knob, you can select the temperature best suited to your application. The Adjustable Spot Cooler provides a precise temperature setting from -30°F (-34°C) to room temperature.

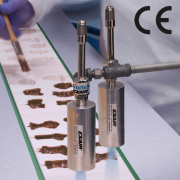

Mini Cooler

A proven way to reduce downtime and increase productivity on a variety of operations involving small parts where heat is a problem. EXAIR’s Mini Cooler produces a stream of 20°F (-7°C) cold air to prevent heat build-up. The Mini Cooler is particularly effective on high speed operations to prevent burning, melting and heat related breakage. Operation is quiet (76 dBA) and there are no moving parts to wear out.

Catalogs

Vortex Tubes Spot Cooling Catalog (2 MB)

Vortex Tubes Spot Cooling Catalog (2 MB) Application Assistance Form (147 KB)

Application Assistance Form (147 KB) Vortex Tube Installation (285 KB)

Vortex Tube Installation (285 KB) Cold Gun Installation (251 KB)

Cold Gun Installation (251 KB) Adjustable Spot Cooler (251 KB)

Adjustable Spot Cooler (251 KB) Mini-Cooler Installation (221 KB)

Mini-Cooler Installation (221 KB)The Basics of the Line Vac

Learn MoreElectronic Flow Controller

EFC is a user-friendly electronic flow control for compressed air that is designed to minimize compressed air use on blow off, drying, cooling, conveying and static elimination operations.

Learn More