S600 Portable Compressed Air Purity Analyzer

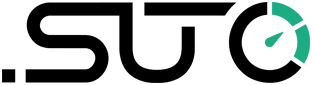

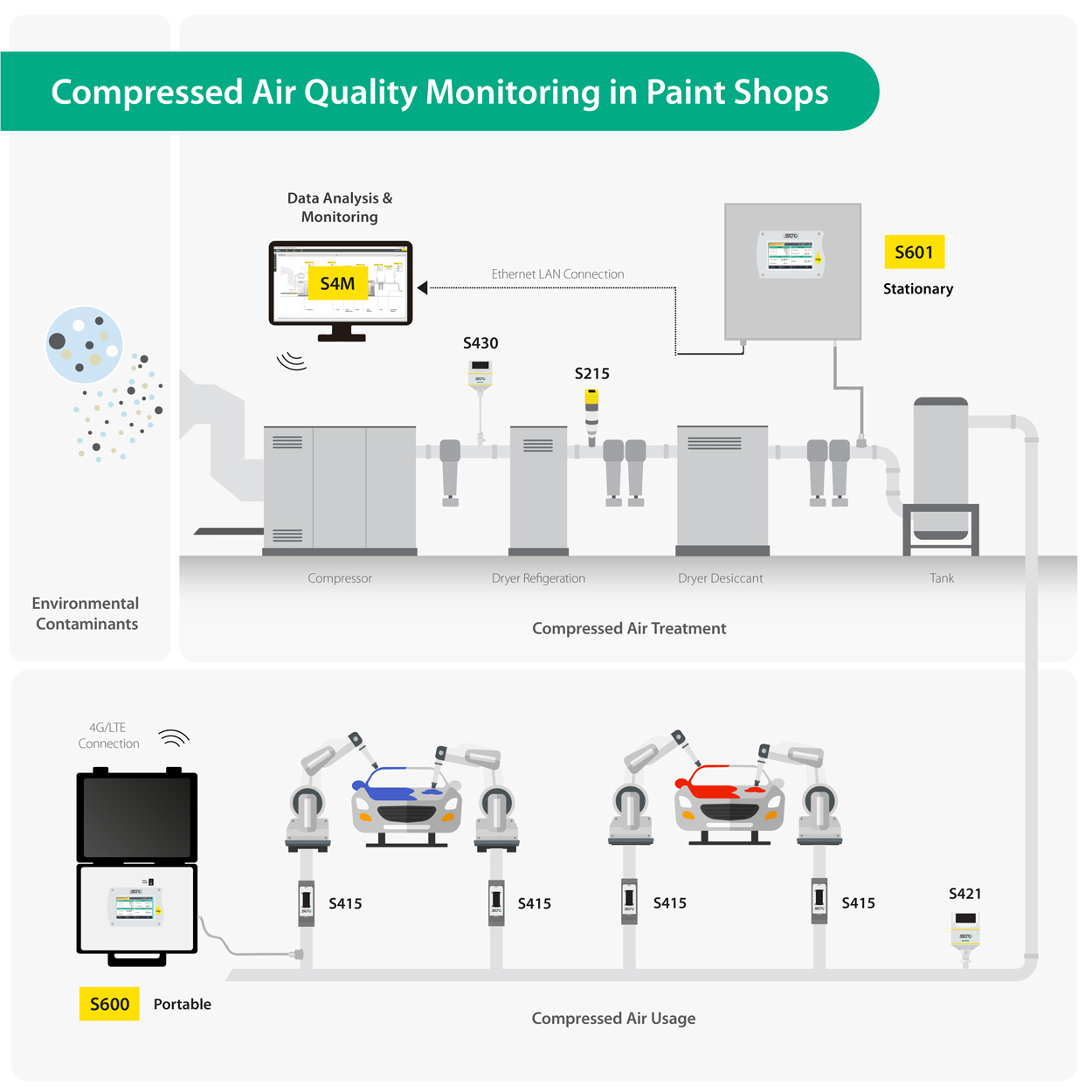

The S600 is the portable multi-tool for compressed air purity measurements. It measures, records, and validates quality parameters like particles, dew point, oil vapor contents, temperature and the pressure of compressed air systems.

- Portable: weighs just 9.8kg and comes with carrying case

- Advanced: combines latest sensors and software into a single unit

- Versatile: measure particle count, dew point, and oil vapor levels, temperature, and pressure

Description

Description

The S600 Portable Compressed Air Purity Analyzer combines the latest sensor technology, software-guided measurements and a time-saving setup into a handy, touchscreen controlled multi-tool that can be carried in one hand. Offering metrics on dew point, oil vapor content, particle content, and more, the S600 provides everything you need and more to spot-check air quality.

Benefits

Fewer Errors

one set of measurements reduces margin of error

Complete Convenience

take every measurement at once without switching tools

Improve Overall System Health

Keep compressed air cleaner

Applications

Applications

- Particle Concentration Measurement

- Measurement methods according to ISO 8573 standards (together with isokinetic sampling device)

- Latest laser detection technology

- Smallest particle size 50 % per JIS, bigger sizes 100 % per JIS

- Dew Point Measurement

- Large ranges thanks to the unique multiple sensor technology

- Long-term stable and well-proven measurement methods

- High precision with an accuracy of ±2 °C Td OIL VAPOR MEASUREMENT

- Latest photoionisation detector (PID) with self-calibration

- Wide range of oil vapor concentrations

- High precision with 5 % of reading ± 0.003 mg/m³ accuracy

- Pressure Measurement

- State of the art sensor technology

- Additional quality data about the compressed air system

- Plug and Play Measurements at a Touch

- Integrated data logger records all channels in parallel for later analysis

- 5’’ touchscreen allows you to interact with the device on site. There is no need for a PC to manage the device.

Specs

Specs

-

-

- Measuring unit: 5” colour touchscreen with data logger, guided measurement and report generator function. All combined and integrated with the multiple sensor system.

- Process connection: Connection tube 1.5 m with compressed air coupling

- Operating pressure: 0.3 … 1.5 MPa

- Ambient temperature: 0 … +50 °C

- Storage & Transport temperature: -10 … + 70 °C

- Medium: Compressed Air, Nitrogen N2, Carbon dioxide CO2 (software setting)

- Medium temperature: 0 … + 40 °C

- Medium humidity: < 40 % rH, no condensation

- Reference settings: ISO1217 20 °C 1000 mbar

- UV lamp lifetime (oil vapor sensor): 6000 working hours

- Power supply: Mains supply adapter (AC/DC); Input: 100 … 240 VAC, 50/60 Hz, 1.4 A; Output: 24 VDC, 2.5 A, 60 W max.

- Data logger: 100 mio. values, Integrated report generator for PDF export

- Measured values: Temperature, Pressure, Oil vapor, Dew point, Particle concentration

- Interface: USB, Modbus TCP

- Display: Touchscreen, Size: 5“, Resolution: 800 x 480 px

- Dew point sensor: Dual-sensor technology (QCM & Polymer)

- Particle sensor: Laser optical detection

- Oil vapor sensor: PID (Photoionisation detector)

- Measurement duration: min. 35 minutes (no upper limit)

- Sampling rate: 1 sample / sec.

- Classification: IP65 (cover lid closed)

- Casing material: PC + ABS, Al alloy

- Weight: 9.8 kg

- EMC: IEC 61326-1

- Measurement range: Particle counter 0.1 < d ≤ 0.5 μm ; 0.5 < d ≤ 1.0 μm ; 1.0 < d ≤ 5.0 μm

- Measurement range Dew point sensor: -100 … +20 °C Td

- Measurement range Oil vapor sensor: 0.003 … 10.000 mg/m3

- Detection limit oil vapor sensor: 0.003 mg/m3

- Resolution oil vapor sensor: 0.001 mg/m3

- Accuracy Particle measurement: 50 % @ 0.1 < d ≤ 0.15 μm 100 % @ 0.15 μm > d per JIS

- Accuracy Dew point measurement: ±2 °C Td

- Accuracy Oil vapor measurement: 5 % of value ± 0.003 mg/m3

-

General Specifications Isokinetic sampling device

-

- Measuring unit: Sampling pipe with integrated isokinetic sampling tube, flow regulation and control by integrated flow sensor, to be used for particle measurements according to ISO8573

- Process connection: Connection tube 1.5m with compressed air coupling; 1 compressed air coupling inlet; 2 quick connections to S600; connection tubes to S600 included

- Operating pressure: 0.3 … 1.5 MPa

- Ambient temperature: 0 … +50 °C

- Storage & Transport temperature: -10 … +70 °C

- Flow sensor: Thermal mass flow, only for isokinetic flow setup, no system-flow measurement

- Interface: Communication interface for S600, cable included, M8

- Accuracy: 3 % o. RDG

- Purge flow: Regulated by needle valve, setup guided by S600

Documents

S 600 - Catalog

S 600 - Catalog (1 MB)

S 600 - Catalog (1 MB)S 600 Manual

S 600 Manual (3 MB)

S 600 Manual (3 MB)