EXAIR UNVEILS THE GEN4 SUPER ION AIR KNIFE

Increase Surface Cleanliness, Product Quality, and System Performance with One Simple Installation

As rugged and as production lines often are, they can quickly become temperamental when introduced to too much foreign matter. Foreign matter can be anything from dust pulled in by way of static electricity to fragments of recently refined products to simple condensation, all of which will likely be introduced into any given production line at some point. Over time, enough particle buildup can lead to a great deal of system inefficiency, even causing costly downtime or damage to expensive system components.

Keeping Your System Up and Running

At Airtec, one of our primary goals is to help you use compressed air to achieve new levels of efficiency, so when we hear about new and extraordinary products that can help us accomplish this goal, we jump at the chance of telling you about them.

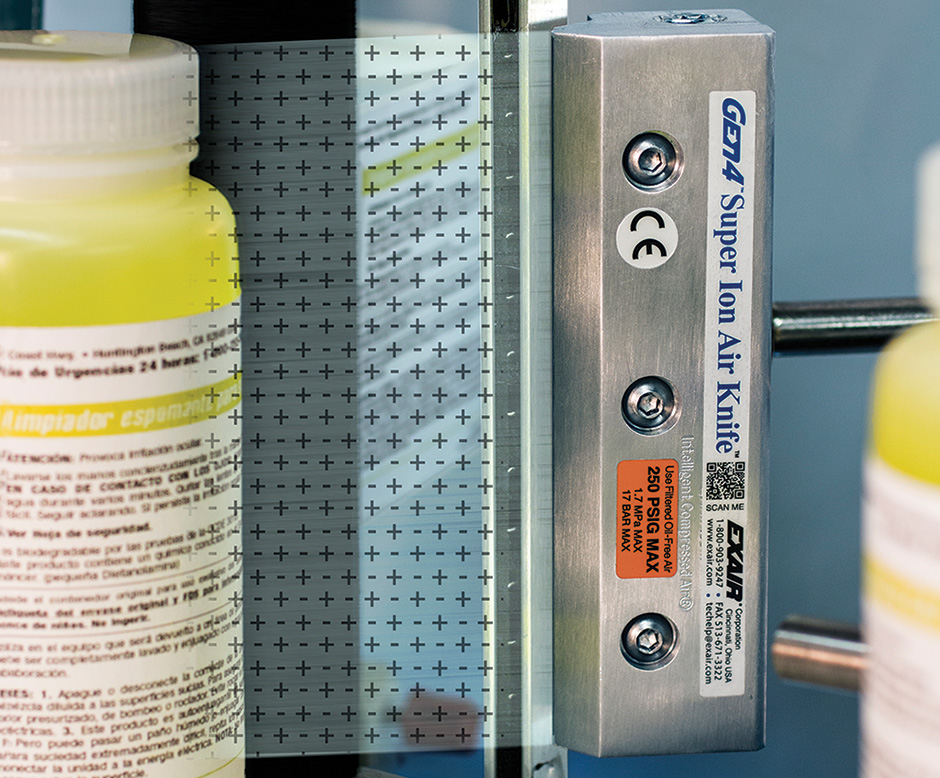

Once again, Exair has improved upon their already formidable designs and taken the next step in using air compression to increase production efficiency. The Exair Gen4 Super Ion Air Knife is the perfect way to clean up any system, reducing static and clearing systems of all manner of debris. With the Gen4 Super Ion Air Knife, you can increase production speeds, product quality, and overall system efficiency.

What Makes the Gen4 Super Ion Air Knife Special

In our last blog, we explored the importance of static elimination as well as the dangers of static buildup. Exair’s new Air Knife, among other things, functions as an additional safeguard against static buildup. The Gen4 Super Ion Air Knife uses a specialized stream of air to launch static-eliminating ions toward its target, reducing static electricity at low inlet pressures at a rate 34% higher than its competitors. The Gen4 Super Ion Air Knife seamlessly incorporates Exair’s previous designs to minimize compressed air use by inducing surrounding airflow at an incredible ratio of 40:1. The unique amplified airflow eliminates static charges in less than a half second, and air volume and velocity can be controlled and fine-tuned from a “breeze” to a “blast,” allowing you to place it as needed.

All of the Gen4 products have undergone independent lab tests to certify they meet the rigorous safety, health and environmental standards of the USA, European Union and Canada, attaining CE and UL marks. They are fully RoHS compliant and include a metal armored high voltage cable to protect against abrasion and cuts, integrated ground connection, and electromagnetic shielding. The Gen4 Super Ion Air Knife is available in sizes ranging from 3 inches to 108 inches long.

Our Role

At Airtec, we work hard to show the world the power of efficient compressed air, and one of the most important ways we can help is by providing only the highest quality product recommendations. We make recommendations on a specific set of criteria geared toward help you increase efficiency, save money, and build a better overall system. The Gen4 Super Ion Air Knife is just one simple, cost-effective way to help you bring new levels of efficiency and reliability to your production line. Contact us today and find out more about the valuable asset that is efficient compressed air.

The Basics of the Line Vac

Learn MoreElectronic Flow Controller

EFC is a user-friendly electronic flow control for compressed air that is designed to minimize compressed air use on blow off, drying, cooling, conveying and static elimination operations.

Learn More