ISO 8573-1 Compressed Air Quality Audit

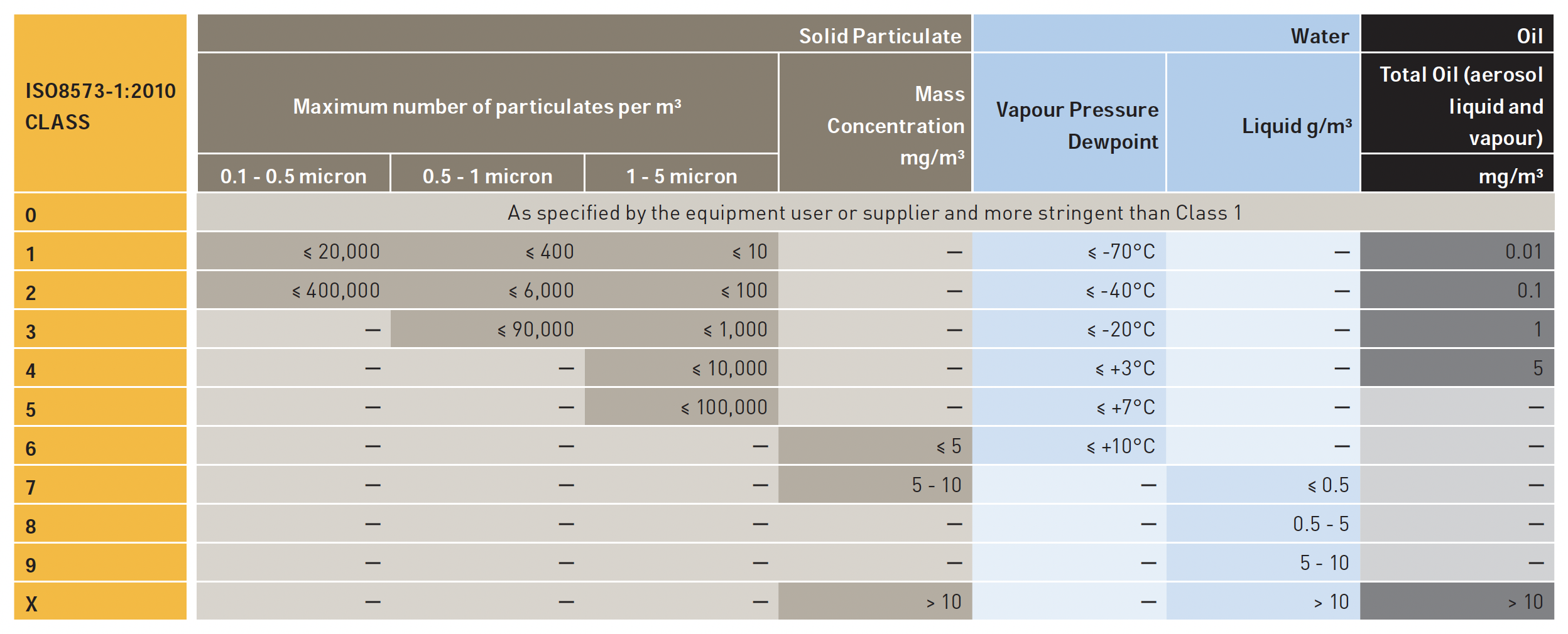

For facilities that require higher compressed air standards, our ISO 8573-1 Compressed Air Quality Audit reveals the particle count, oil vapor level, and dew point in every area of your compressed air system. In just 1 day, our specialized audit uncovers anything keeping you from operating within ISO 8573-1 standards. From there, you can more easily maintain the air purity levels you need to:

- Reach and exceed compliance regulations

- Lower maintenance costs through cleaner compressed air

- Reduce monitoring workload for personnel

Our team of compressed air experts combs through your system, measuring compressed air quality for every operation. We use cutting-edge compressed air monitoring equipment to deliver pinpoint-accurate readings from across your system. After taking readings on particle count, oil vapor level, and dew point, we generate a report to be delivered within 24 hours. From there, we can recommend solutions and equipment to help you reach ISO 8573-1 quality standards if need be.

The standards outlined in ISO 8573-1 are rigorous, but they aren’t just for high-purity facilities. Though some industries, such as food and pharmaceutical production, require strict adherence to ISO 8573-1 standards, many don’t require this level of compressed air quality. However, we’ve found that in many cases, adherence to higher compressed air quality standards actually tends to lead to savings over the course of even just a few years. Better compressed air quality nearly always leads to better performance from equipment, lower maintenance costs, significantly lower energy expenditure, and less production downtime.

If you’re interested in learning about our ISO 8573-1 Compressed Air Quality Audits, please feel free to reach out to us today! We offer free quotes on all of our solutions, and we are eager to help you reach a cleaner, more energy efficient future.

The Basics of the Line Vac

Learn MoreElectronic Flow Controller

EFC is a user-friendly electronic flow control for compressed air that is designed to minimize compressed air use on blow off, drying, cooling, conveying and static elimination operations.

Learn More