Choosing the Right Air Compressor

While there are many high-tech products and efficient solutions for nearly every stage of the compressed air system, there is absolutely no replacement for the perfect air compressor. Whether you’re running a small machine shop or overseeing a massive manufacturing facility, using the right compressor is paramount to successful operations.

Finding the Compressor that Fits Your Needs

When selecting a new compressor, there is a lot to keep in mind, but one of the best ways to start is by asking yourself the following questions.

- How much air pressure do I need?

- How much air flow do I need

Despite their apparent similarities, air flow and air pressure are quite different from one another, accomplishing very different goals:

- Air Pressure (PSI = pounds per square inch) refers to how much power is needed to accomplish a specific goal at any given moment.

- Example: It may take 10 psi to make a block move along a table. Anything less, and the block won’t move

- Air Flow (CFM = cubic feet per minute) refers to how much air is needed to repeatedly accomplish a goal.

- Example: Pneumatic cylinder uses 30 cfm of air to operate properly. Any less, and the cylinder won’t be able to operate with any consistency.

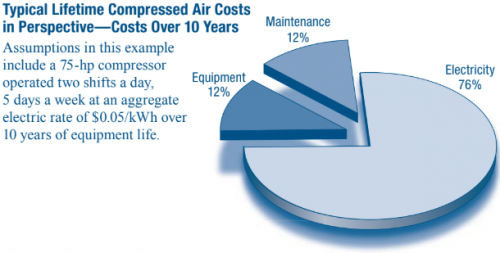

These concepts go a long way in choosing the correct compressor. One of the most common mistakes made when purchasing a new compressor is oversizing, leading not only to massive inefficiencies and resource waste, but also to many mechanical problems.

Because air compressors generally feed air intermittently at different levels, some degree of storage is usually in play. If a compressor is too large, the amount of air generated will not be entirely used after storage, so the compressor ends up storing up small amounts of compressed air and never using it. This isn’t just wasteful, it’s actually harmful to compressor and, over time, can lead to costly breakdowns that may even require replacement.

On the other hand, if the compressor is too small, the lack of performance leads to incomplete tasks and pressure drops throughout the system.

How Airtec Can Help

At Airtec, we work hard to provide perfect solutions for all of our clients, no matter their scale. Purchasing a new compressor is no small task, and we are more than happy to offer our years of expertise in the compressed air industry to help you find the perfect one. We offer free quotes, personal consultations, and custom solutions to provide you with anything and everything you need to operate your system with efficiency.

Additionally, if you want to learn everything you need to know to maintain your own system and make informed air compressor purchases, please feel free to ask us about our compressed air training program. No matter what kind of system you’re operating, you can learn how to make repairs and introduce new level of efficiency to your system.

Contact Airtec today for a free quote or with any questions!

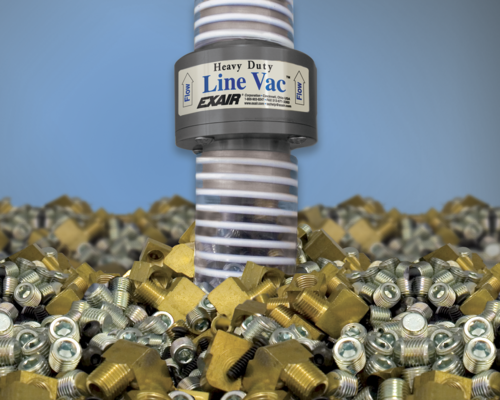

How to increase efficiency on your entire system by eliminating leaks.

How to increase efficiency on your entire system by eliminating leaks. Clean Air Conveyor

Clean Air Conveyor