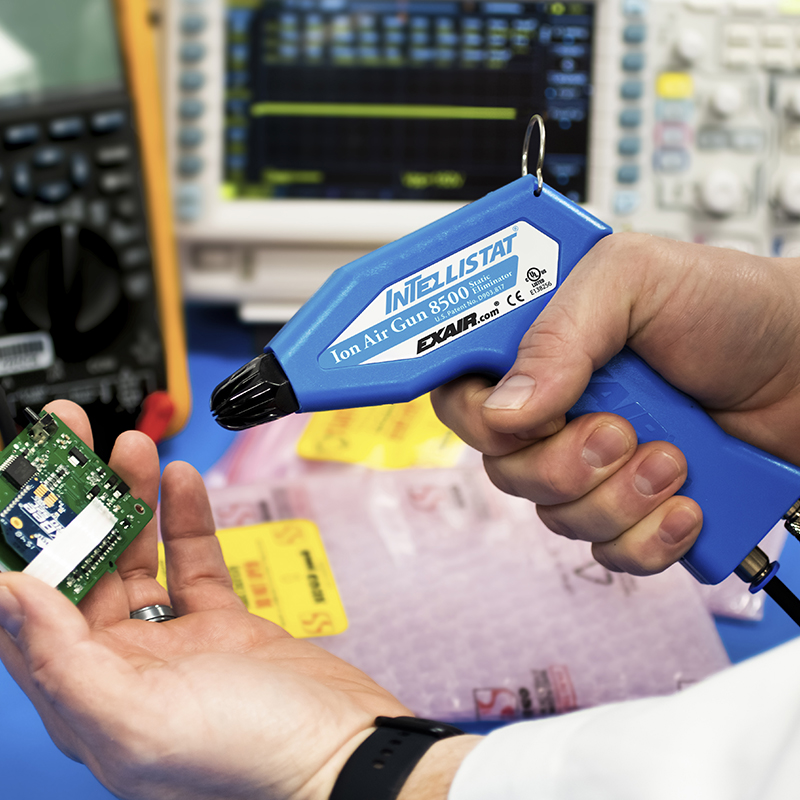

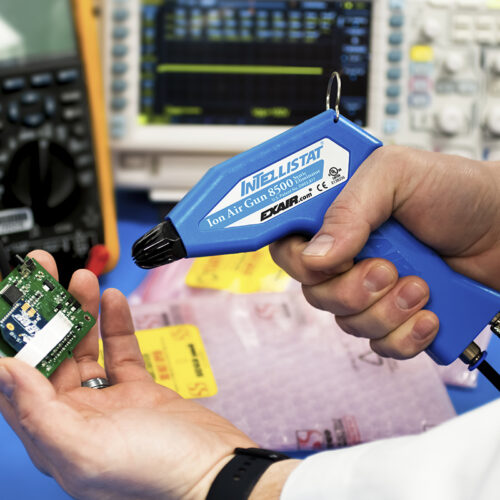

Airtec is happy to present, EXAIR’s patented Intellistat® Ion Air Gun. A handheld and lightweight solution to static elimination in clean processes or sensitive assembly work such as scientific and electronic test facilities, laboratories, and clean rooms. The Intellistat was designed to consume minimal compressed air while simultaneously delivering precise blow-off, and exceptional static decay rates capable of reducing 1000 volts to less than 100 in less than a second at up to 24” away.

This Intellistat is activated with a comfortable, ergonomic short throw trigger which requires minimal effort. Constructed with a low voltage transformer converting 120V to 24V, it was designed to ensure user safety, in addition to using an EXAIR engineered air nozzle to maximize efficiency and meet OSHA requirements for sound level and dead-end pressure. It is equipped with a red/green LED to signify proper functionality, as well as a hook for easy hanging and storage. Made from durable static dissipative polycarbonate, the Intellistat also assures its usefulness in applications requiring non-conductivity such as circuit board or electronics manufacturing or testing.

The Intellistat is a low maintenance solution that is UL listed and CE compliant, providing an excellent addition to EXAIR’s entire Gen4 static eliminator product line including Super Ion Air Knives, Ion Air Cannons, Ion Air Guns, Ionizing Bars and Ionizing Points. Reach out to us today for a free quote on our compressed air solutions.

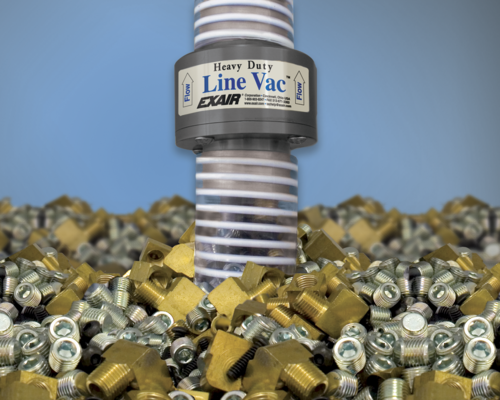

As a constantly-operating part of most facilities, material movement can take a lot of energy to accomplish, whether the transported substances are nuts and bolts, gravel, plastic pellets, food products, pills, or even shavings, sawdust, and other granules.

As a constantly-operating part of most facilities, material movement can take a lot of energy to accomplish, whether the transported substances are nuts and bolts, gravel, plastic pellets, food products, pills, or even shavings, sawdust, and other granules.  At Airtec, we pride ourselves on creating efficient solutions for the common problems facing industrial environments, reducing wasted energy and saving time and money. For the purpose of static elimination, we offer a multitude of efficient solutions, such as the Ion Air Wipe for precision applications, the Ion Air Knife for strategic placement and blowoff, and the Ion Bar for large sheets of plastic, paper, or film. Each of these products are highly efficient and versatile, perfect for strategic use throughout your system. For large scale blowoff and static elimination on flat surfaces, the

At Airtec, we pride ourselves on creating efficient solutions for the common problems facing industrial environments, reducing wasted energy and saving time and money. For the purpose of static elimination, we offer a multitude of efficient solutions, such as the Ion Air Wipe for precision applications, the Ion Air Knife for strategic placement and blowoff, and the Ion Bar for large sheets of plastic, paper, or film. Each of these products are highly efficient and versatile, perfect for strategic use throughout your system. For large scale blowoff and static elimination on flat surfaces, the