No matter your industry, using resources efficiently is an important part of successful and fiscally responsible operation, but in the case of industrial or manufacturing facilities that rely heavily on compressed air, efficient resource use isn’t just a goal, it’s a necessity, both for the facility and the environment.

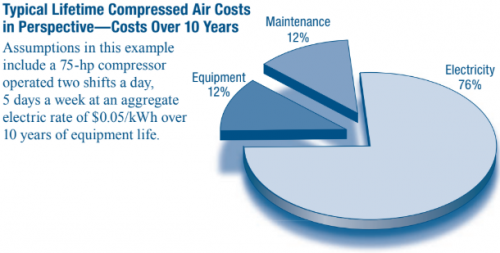

A recent U.S. Department of Energy survey revealed that in a typical industrial facility, around 10% of the consumed electricity is used to generate compressed air, but in some cases, up to 30% of consumed electricity is used for compressed air generation. When so much energy is at stake, waste cannot be tolerated, especially when efficiency goals must be met, but it’s important to remember that efficiency doesn’t only impact your bottom line. Compressed air inefficiency sometime has a much bigger impact than anticipated.

A Much Bigger Impact

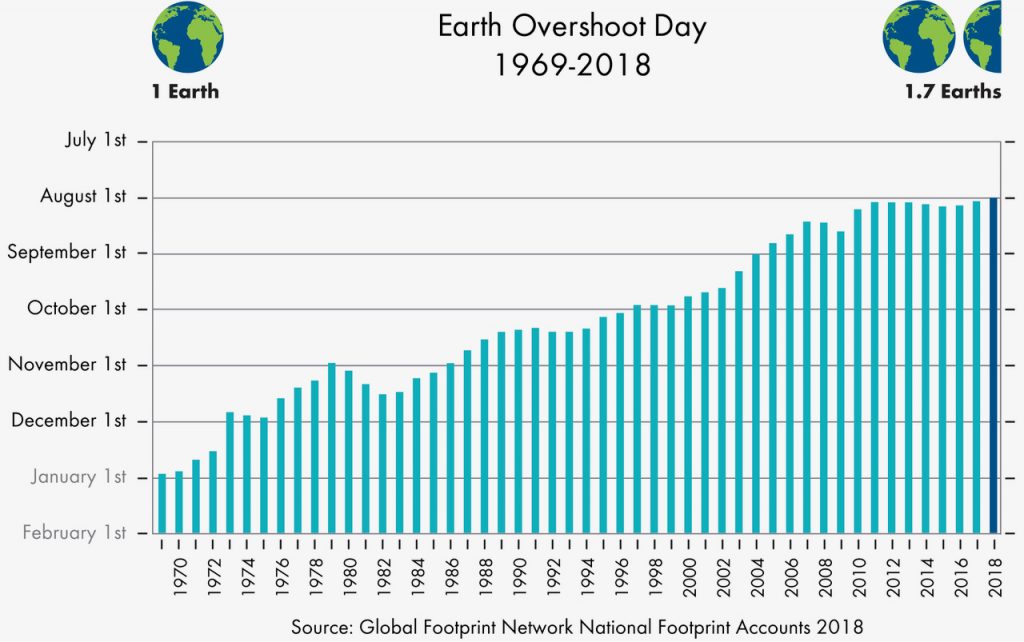

As some of you may already know, 2018’s Earth Overshoot Day was on August 1. If you’re unfamiliar with the concept, Earth Overshoot Day is the point in the year at which our demand for natural resources exceeds what our planet can renew. This year, Overshoot Day occurred on August 1, just 7 months into the year. To put that into perspective, when Overshoot Day was first conceived in 1970, it occurred on December 29, just 2 days shy of a fully sustainable year. Over the last several decades, Overshoot Day has steadily occurred earlier in the year, until culminating in this year’s Overshoot Day, which is the earliest it has ever been.

Seeing numbers like this can be unnerving, even paralyzing, but it’s important to remember that there are steps we can take every day to minimize environmental impact. In the case of facilities that utilize compressed air, minimizing environmental impact and saving money go hand-in-hand.

Increasing Efficiency

Inefficient compressed air use is among the most common ways manufacturing and other industrial facilities lose money. Take for example, a small 100 HP air compressor. An air compressor this size uses enough energy to sustain 1,800 people on any given day. Unfortunately, a typical system loses about 20% of produced compressed air. So even a 100 HP compressor ends up wasting enough energy to sustain 300 people, senselessly costing your company thousands of dollars and throwing away valuable energy.

At Airtec, we specialize in creating custom solutions designed to help save money through efficient compressed air use. By proposing efficient solutions and introducing high-quality products wherever they are necessary, we are able to ensure that your system functions at its peak, all while reducing both energy consumption and negative global impact.

With Airtec, good for the environment and good for your bottom line aren’t mutually exclusive. Get started saving your valuable compressed air today! Call or email us for a quote, and learn more about how you can achieve compressed air efficiency.

How to increase efficiency on your entire system by eliminating leaks.

How to increase efficiency on your entire system by eliminating leaks.

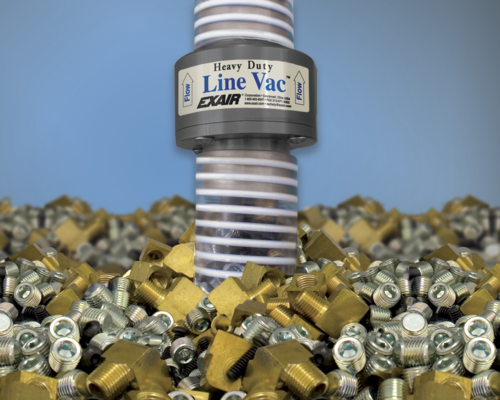

Clean Air Conveyor

Clean Air Conveyor Cabinet Coolers actually have two functions that they can bring to your system. They can stop your cabinets from overheating and causing permanent damage to precision instruments, and they can prevent contaminants like moisture or dust from building up, preserving delicate sensors and equipment. However, their primary function is keeping your system cool.

Cabinet Coolers actually have two functions that they can bring to your system. They can stop your cabinets from overheating and causing permanent damage to precision instruments, and they can prevent contaminants like moisture or dust from building up, preserving delicate sensors and equipment. However, their primary function is keeping your system cool.