From small machine shops to fully-equipped manufacturing lines, Airtec has long been in the business of providing efficient compressed air solutions that are powerful, reliable, and cost-effective. We make every effort to utilize our decades of industry knowledge to the benefit of our clients, using carefully-selected brands and products to create our solutions, because one of the most important parts of creating an efficient compressed air solution is knowing which products and brands yield the best, most efficient results. This means that we have our ear to ground constantly, eagerly awaiting new releases from trusted product manufacturers while also watching for new, innovative products on the rise. Among those we’ve noticed making waves in the world of compressed air is SUTO.

SUTO and its technologies represent the future of industry, using data to achieve previously unheard-of levels of efficiency for systems of all shapes and sizes. We’ve touched on Industrial Internet of Things technology in previous blogs, discussing the impressive list of possibilities unlocked by IoT technology, but SUTO takes IoT and its applications a step further, creating a completely modular system that can be set up in any system.

What Does SUTO Do?

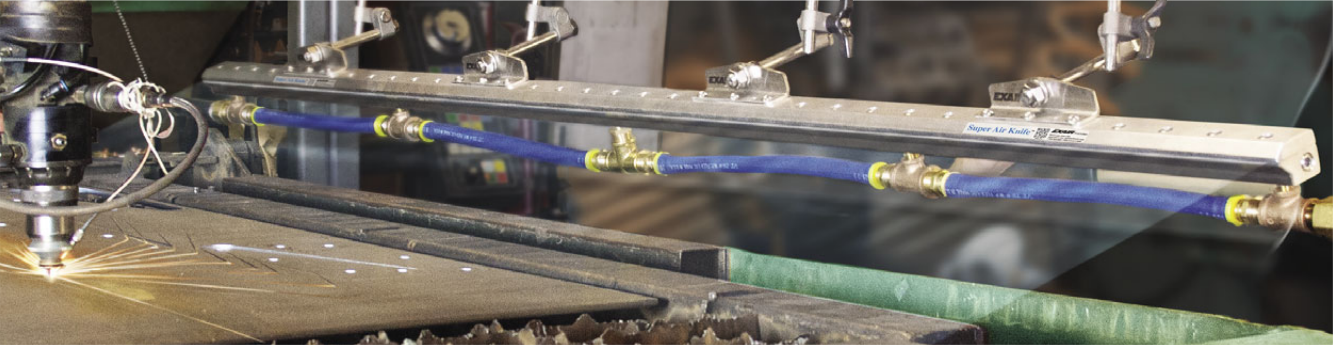

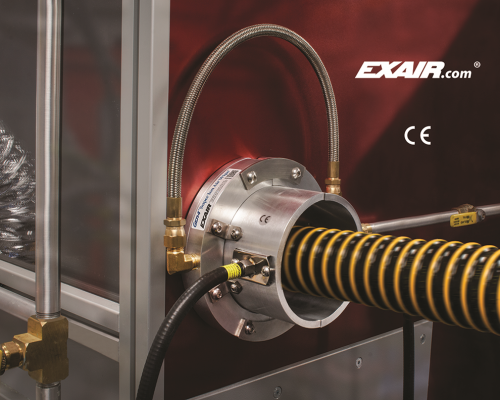

Some of the most important and oft-overlooked parts of compressed air systems are monitoring systems. The readings and data from monitoring systems are the key to discovering where your system is performing best as well as where improvements can be made. The problem is that there are typically only a few points where data is gathered, providing only a limited picture of system performance.

SUTO’s modular monitoring system resolves this issue by gathering data from across your full system, revealing resource waste at previously unmeasured points. What’s more, the modules are all linked via Internet of Things technology, allowing you to view your full system all at once. Planning on adding new components or replacing old? SUTO’s modular system allows you to remove and add sensors as-needed, with new sensors feeding information into the same system as all the others.

Taking the Reigns of New Technology

With SUTO’s monitoring system, you will gain the information needed to locate problem areas, the visibility needed to reveal where equipment updates should be made, and the ability to see and measure the impact of any and all changes you make within your system. If you are seeking new ways to use your compressed air resources efficiently, SUTO and their use of IoT technology provides you with a quick and sustainable way of viewing your system in action. Especially as data analysis and management become a more entrenched part of manufacturing operations, the information SUTO gathers will only increase in importance and value.

If you’re interested in learning more about SUTO and how it might impact your operations, or you’re just interested compressed air efficiency in general, please don’t hesitate to contact us anytime! We offer free quotes on our compressed air solutions, and would love to help you achieve your goals of energy efficiency.